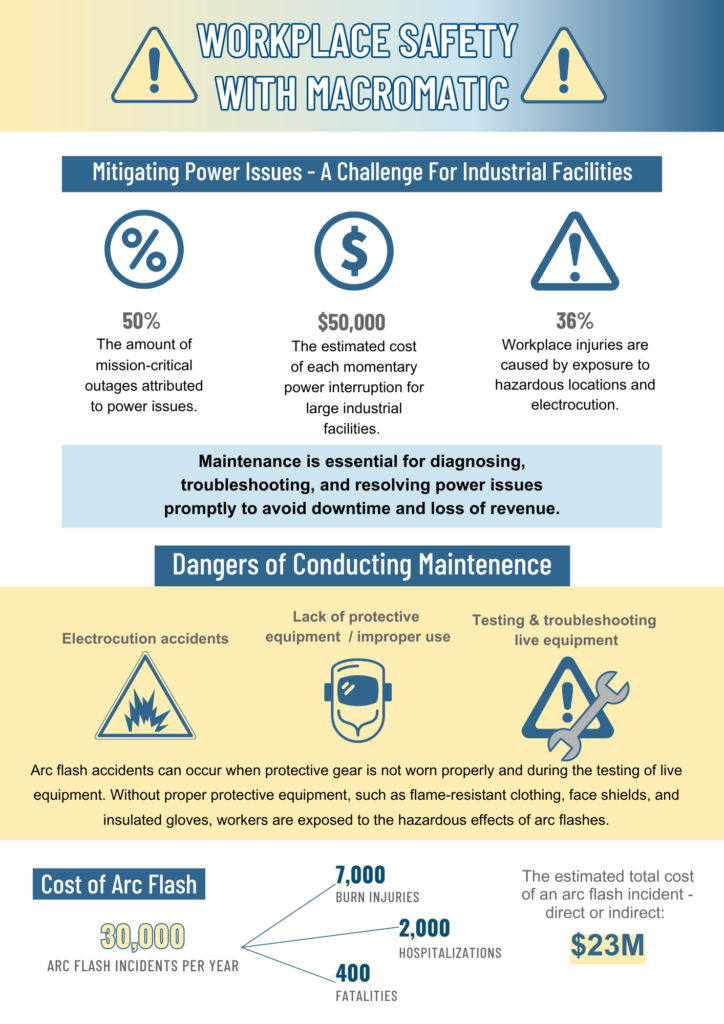

Arc flash is a subject that should be taken seriously. Occurring as the result of a flawed electrical system, an arc flash is a sudden and unexpected release of electrical energy resulting from a fault or short circuit that produces intense heat, light, and pressure; and which can cause severe injury or damage. This condition occurs when electrical current flows through the air between conductors or from a conductor to ground, creating a highly dangerous and explosive event.

Causes Of Arc Flash

Arc flash incidents are triggered by several factors. Common causes are rooted in the electrical infrastructure that combines complex elements, including:

- Human error. Incorrect equipment installation and/or maintenance can initiate unsafe conditions that drive the potential for arc flash incidents.

- Equipment failure. When the integrity of an electrical system is compromised … e.g., insulation breakdown, corrosion, mechanical damage, etc … conditions exist in which an electrical current can escape its intended path. A short circuit would cause the electrical current to arc through the air and initiate an arc flash event.

- Environmental factors. Contaminants such as dust, moisture, and airborne particles can degrade components, thus enhancing conductivity and creating hazardous conditions ripe for arc flash occurrences.

Importance Of Arc Flash Mitigation

Arc flash mitigation in industrial facilities is crucial for safeguarding personnel teams and ensuring operational integrity and resilience. Intentional strategies and proactive measures build a culture of safety through comprehensive risk assessments, training, and investments in technology.

By implementing robust arc flash mitigation strategies, industrial facilities can turn the challenge of electrical hazards into opportunities for growth and innovation. These strategies empower facilities to meet and exceed safety standards … which in turn drives progress in both productivity and employee well-being.

Arc Flash Mitigation Strategies

Effective arc flash mitigation strategies involve deliberate planning, a thorough understanding of electrical systems, technology integration, and proactive risk assessments. Such a strategy allows an industrial facility to:

- Pinpoint and address vulnerabilities.

- Integrate correct Personal Protective Equipment (PPE) and procedures.

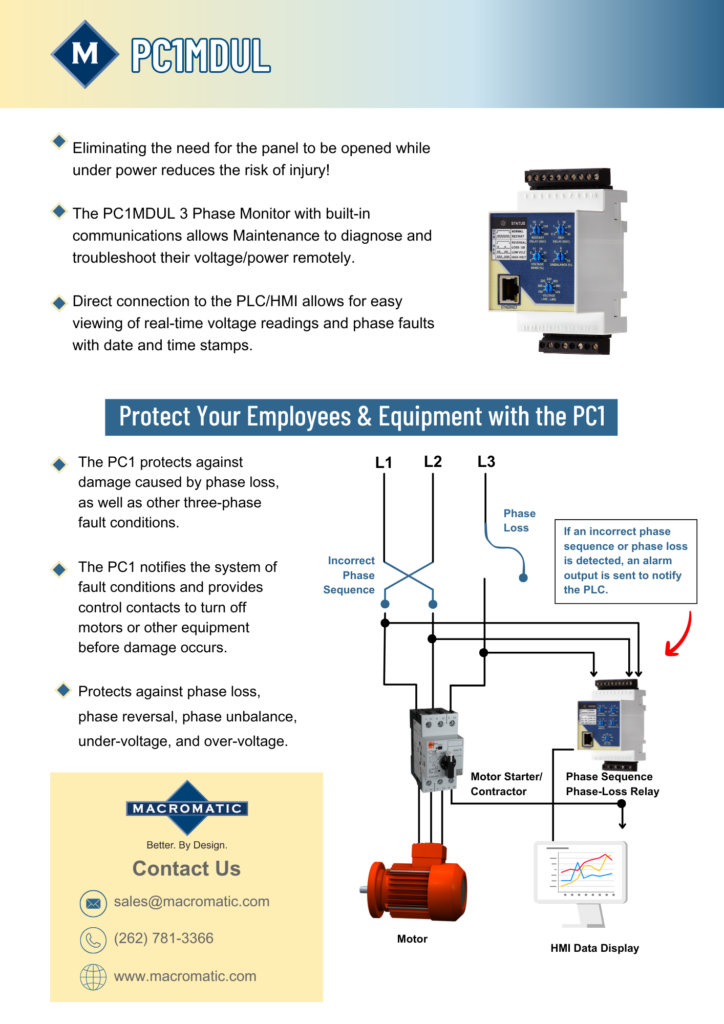

- Leverage innovative technology including arc-resistant equipment, and advanced phase monitoring relay systems such as the “PC1MDUL” (known as the “PC1”) three-phase monitor. Refer to the infographic on the right.

- Enable remote operations with the “PC1”, which prevents the need for electrical panels to be opened under power … therefore minimizing human interaction with the electrical current.

- Proactively train team members in the correct application of safety protocols.

Develop An Arc Flash Mitigation Plan

For an industrial facility to transform its arc flash mitigation strategy into a scalable plan for growth of its existing location and implemented within all its locations, consider the following:

- Create a set of standardized procedures which can be easily adapted and used by all functions within the industrial facility. Consistent safety practices ensure seamless integration as the arc flash mitigation strategy expands to include additional locations.

- Invest in comprehensive training and education programs that enable team members to apply arc flash mitigation measures within their respective work environments. Such training solutions can be tailored to multiple levels of expertise and expanded to accommodate new team members.

- Establish a culture of continuous improvement, by creating a framework for ongoing evaluation and adjustment of the arc flash mitigation strategy. Regular assessment, feedback from team members, and knowledge of the latest industry advancements (e.g., the “PC1MDUL” three-phase monitor) proactively ensures that the industrial facility’s arc flash strategy remains adaptable and scalable over time.

- Foster cross-functional collaboration throughout the industrial facility, to share insights and best practices. This collective effort not only enhances the scalability of the arc flash mitigation strategy, but ensures a culture of safety and innovation throughout the facility.

Conclusion

Trystar’s Waukesha WI location (formerly known as Macromatic Industrial Controls) manufactures the “PC1” showcased above.

We invite you to contact one of our Application Specialists to discuss your three-phase monitoring and industrial arc flash mitigation needs!